How Hanger Bolt to Drill on Metal Roof Steel Purlins

Jan 30, 2026

For solar installers and project engineers, the choice of fasteners can make or break a project's timeline, budget, and long-term reliability. Landpower Solar’s Solar Hanger Bolt for Steel (LP-HB-S) represents a significant leap in mounting technology, specifically engineered to transform how commercial and industrial rooftop PV systems are secured. This blog delves into the design, performance, and advantages of this critical component.

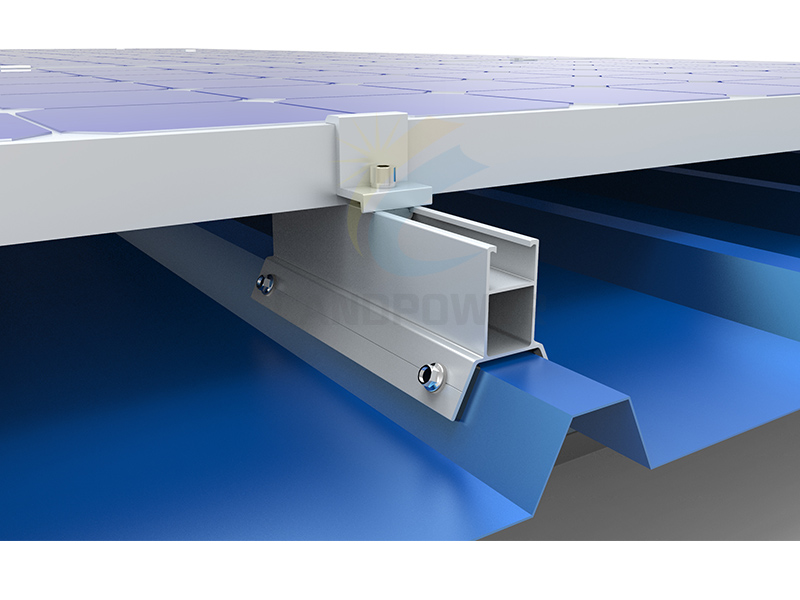

The Core Innovation: A Two-in-One Fastening Solution

At its heart, the LP-HB-S is an elegantly simple yet powerful innovation. It ingeniously combines the functions of a standard bolt and a threaded stud into a single, robust component. This integrated design enables a direct, rigid, and safe connection between the solar module mounting rails and the underlying steel purlins—eliminating the need for welding, drilling separate holes, or using multiple adapters.

This breakthrough addresses common pain points in steel roof installations:

Time Efficiency: Streamlines the installation process into a single-step operation.

Cost Reduction: Lowers labor costs and reduces the number of parts needed per mounting point.

Structural Integrity: Creates a direct metal-to-metal joint, minimizing potential failure points.

Unmatched Technical Specifications for Demanding Environments

Landpower Solar builds the LP-HB-S with specifications that meet the rigorous demands of large-scale, long-life solar installations.

Material & Strength: Manufactured from high-grade Carbon Steel 1022A/10B21 and heat-treated to achieve a Property Class of 8.8. This ensures exceptional tensile and yield strength, providing the backbone to withstand extreme mechanical loads from high winds, heavy snow, and seismic activity.

Superior Corrosion Protection: The fastener features a Zinc-Nickel Alloy Plating surface finish. This coating offers far superior corrosion resistance compared to standard galvanization, crucial for protecting the asset over decades of exposure to diverse weather conditions.

Proven Longevity: Backed by a 12-year warranty and a twenty-year expected service life, the LP-HB-S is an investment in the long-term operational stability of your PV plant.

Compliance & Certification: The product carries CE, TUV, and ISO certifications, providing independent verification of its safety, performance, and manufacturing quality for global projects.

Key Performance Advantages in Real-World Applications

1. Rapid Installation & Significant Cost Savings

The LP-HB-S is designed for efficiency. Its self-drilling tip allows installers to drill and tap its own hole in the steel purlin in one step when driven with a standard electric drill or screwdriver. This eliminates pre-drilling, drastically reducing installation time, labor costs, and on-site safety risks. For high-volume projects, specialized automated tools can be used for even greater speed.

2. Exceptionally Reliable & Secure Connection

The bolt forms a robust, vibration-resistant joint directly with the steel structure (C-purlins, Z-purlins, square tubes, etc., typically 1.5mm thick). This connection offers excellent pull-out and shear resistance, ensuring the mounting system remains secure under dynamic loads over its entire lifespan.

3. Durability That Lowers Lifetime Costs

The combination of high-strength carbon steel and advanced Zinc-Nickel plating ensures long-term mechanical stability and fights corrosion. This dramatically reduces the risk of maintenance or premature replacement due to fastener failure, thereby lowering the total lifecycle operations and maintenance (O&M) costs of the solar power plant.

Why Landpower Solar is Your Trusted Partner

Choosing the LP-HB-S means partnering with an industry leader committed to quality and reliability.

13 Years of OEM/ODM Expertise: As a leading solar mounting manufacturer in China with over a decade of specialized experience, Landpower Solar possesses deep, factory-level expertise in design and manufacturing.

Globally Proven Performance: Their products are trusted in over 50 countries, validated by a wide range of climates and operational conditions.

Partnership-Driven Value: The company operates on a philosophy of "less profit, long-term mutual benefit," offering competitive pricing without compromising on the quality that ensures your project's success.

The Bottom Line for Project Success

In solar installations, the smallest components often carry the greatest responsibility. The Landpower Solar Hanger Bolt for Steel (LP-HB-S) is more than just a fastener; it's a strategic component engineered for efficiency, strength, and longevity. By reducing installation complexity, ensuring a dependable connection, and providing certified durability, it directly contributes to a lower levelized cost of energy (LCOE) and a more resilient solar asset.

For project planners and installers looking to optimize commercial and industrial rooftop PV deployments, specifying the LP-HB-S is a clear decision for enhanced performance and peace of mind.

Please click here for more details on Hanger Bolt for Steel Purlins